Tele-remote control is divided into three parts: Fixed hydraulic crusher remote control system, Mine electric locomotive unmanned remote control system, Trackless equipment (LHD Loader) remote intelligent remote control system.

HOT has made a preliminary exploration on the tele-remote control which can meet the construction requirements of the domestic intelligent unmanned mine remote control and automatic mining demonstration area. Tele-remote control is modified in the original models of electrical and hydraulic system design, electronic control system to join the communication system and remote control procedures and remote control system, in order to achieve remote control system on the field device operating functions of the remote control.

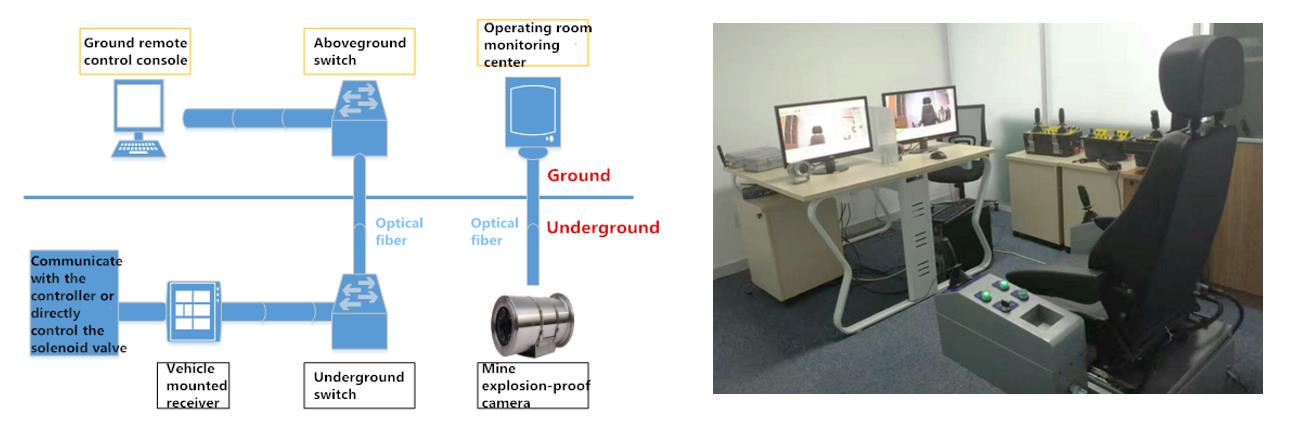

Tele-remote control process

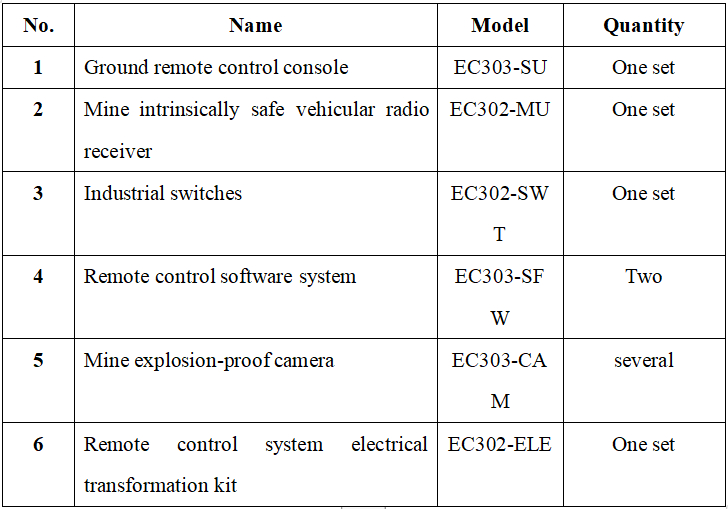

The main system configuration

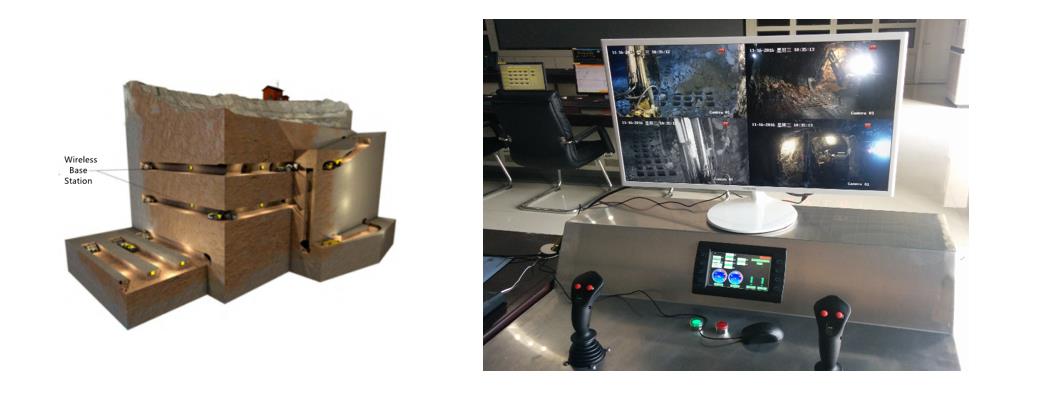

The application of the Tele- remote Control System is shown in the figure above. In the figure above, the house represents the ground control center, and the yellow square is the wireless base station. Simply put, the Tele- remote Control System is an ergonomic remote control console for mining equipment and an important part of the central control room.

The operating mechanism such as the handle on the console can remotely control the driving and actions of the equipment. The operator performs necessary operations on the knobs, buttons and handles on the console. This operation is compiled by the controller and sent to the host computer. And then remotely control the start, shift, steering, throttle and brake of the scraper through the wireless network, so that it can drive at the required speed and route, so as to realize the remote control and monitoring of the mining equipment.

At the same time, the mining equipment transmits real-time images of front and rear road conditions and video signals of operating parameters to the upper computer display installed on the console through the wireless network, so that the driver can remotely grasp the real driving environment of the scraper in real time. In order to monitor the operation of the equipment, the equipment, people (remote control driver) and remote control console (remote control platform, wireless router, camera, control system, etc.) constitute a closed-loop control system.

Tele-remote control system console

Mine intrinsically safe vehicular radio receiver

EC302-MU mine intrinsically safe vehicle radio receiver for complex walking operations machinery. With ultra-modern 32-bit triple-core technology and 72MHz clock frequency and parallel processing capabilities, the controller in the performance of a new upgrade.

The application field extends from the programmable control of the proportional electromagnet and the extra switching function to the coordination of the travel drive and drive control, as well as the walking machine high complexity control circuit. Up to 32 outputs (0% *Vbat to 100% * Vbat), 4 analog inputs, 8 digital inputs, and 1 CAN bus for intelligent communication. These control units provide a high-performance platform for all functions of the walking machine.

Production Automation

1.Automated Steer and Dump with higher accuracy

2.Automated or Remote Control Loading

3.Keep operators far away from working face:

4.One operator can control multi equipment

5.Customized Solutions based on specific mining conditions:

6.Tele remote v1.0: easy to install and remote control

7.Tele remote v2.0: one equipment / Single production area, Automated operation

8.Tele remote v3.0: Multi equipment remote controlled, and 1-in-1 production automated operation

Features

1.Remote Operation & lower Risk

2.Anti-Collision system

3.Automated Load and Dump

4.Higher Equipment Utilization

5.Equipment Monitoring & Reduce Maintenance cost

Extended Features

1.Anti-Collision between tunnel and equipment

2.Access control in production area & Emergency system

3.Equipment Monitoring & Maintenance system

.....